(c) Connecticut Explored Inc. Spring 2009

Subscribe/Buy the Issue!

David J. Corrigan of West Hartford is museum curator at the Museum of Connecticut History, a member of the CT Explored editorial team, and served as a guest editor for this issue. He says he chose to write about the L’Hommedieu auger “to explore a little bit different angle on Connecticut maritime history, approaching it from the point of view of manufacturing objects used in the maritime trades.” He would still love to solve the mystery “Who is D.J. L’Hommedieu?” Corrigan is in the midst of acquiring and cataloging Connecticut-made tools in the Museum of Connecticut History.

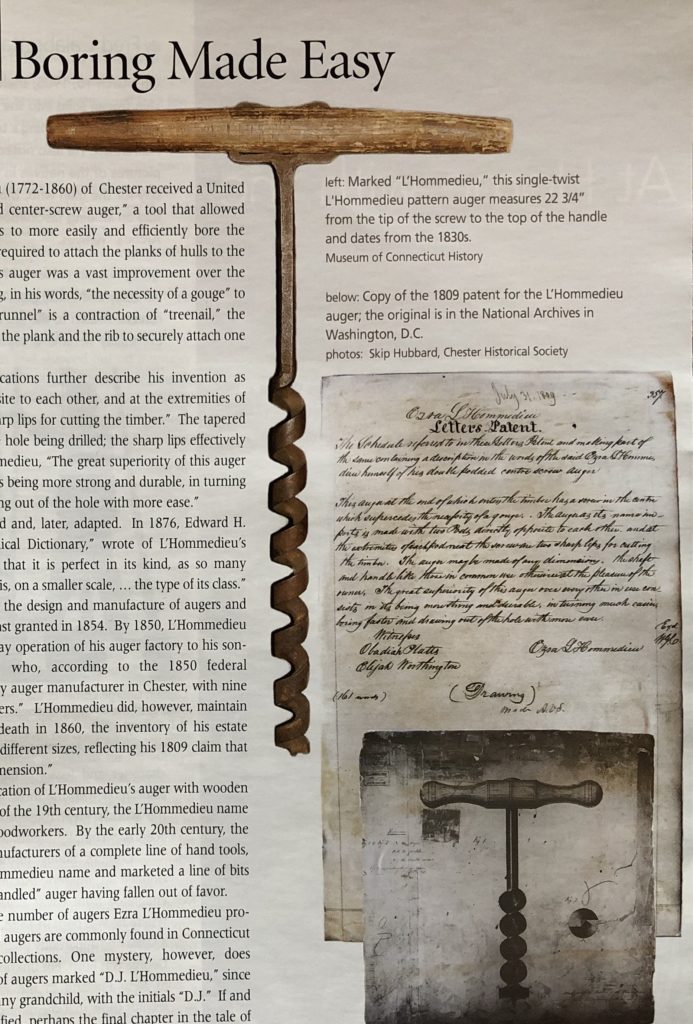

On July 31, 1809, Ezra L’Hommedieu (1772-1860) of Chester received a United States patent for his “double-podded center-screw auger,” a tool that allowed builders of wooden boats and ships to more easily and efficiently bore the hundreds, even thousands, of holes required to attach the planks of hulls to the ribs of their vessels. L’Hommedieu’s auger was a vast improvement over the then-current technology, superceding, in his words “the necessity of a gauge” to create holes for the “trunnels.” (“Trunnel” is a contraction of “treenail,” the wooden spike driven into the hole of the plank and the rib to securely attach one to the other.)

L’Hommedieu’s patent specifications further describe his invention as “made with two pods directly opposite each other, and at the extremities of each pod next the screw are two sharp lips for cutting timber.” The tapered screw kept the auger centered in the hole being drilled; the sharp lips effectively cut the wood. According to L’Hommedieu, “The great superiority of this auger over every other in use consists in its being more strong and durable, in turning much easier, being faster and drawing out of the hole with more ease.”

The auger was widely adopted and, later, adapted. In 1876, Edward H. Knight, in his “American Mechanical Dictionary,” wrote of L’Hommedieu’s invention “It is hardly fair to say that it is perfect in its kind, as so many improvements have followed; but it is, on a smaller scale,… the type of its class.” L’Hommedieu continued to address the design and manufacture of augers and received several more patents, the last granted in 1854. By 1850, L’Hommedieu appears to have ceded the day-to-day operation of his auger factory to his son-in-law, Samuel Carlos Silliman, who, according to the 1850 federal Manufacturing Census, was the only auger manufacturer in Chester, with nine other residents listed as “auger makers.” L’Hommedieu did, however, maintain an interest in his firm; upon his death in 1860, the inventory of his estate listed 1,879 “finished augers” in 33 different sizes, reflecting his 1809 claim that “The auger may be made of any dimension.”

Although the original identification of L’Hommedieu’s auger with wooden shipbuilding had waned by the end of the 19th century, the L’Hommedieu name retained a certain cachet among woodworkers. By the early 20th century, the C.E. Jennings Co. of Yalesville, manufacturers of a complete line of hand tools, had acquired the rights to the L’Hommedieu name and marketed a line of bits for use in bit braces, the older “t-handled” auger having fallen out of favor.

While no hard estimate of the number of augers Ezra L’Hommedieu produced exists, L’Hommedieu-marked augers are commonly found in Connecticut museum and historical society collections. One mystery, however, does remain- the identity of the maker of augers marked “D.J. L’Hommedieu,” since Ezra had no child, nor apparently, any grandchild, with the initials “D.J.” If and when “D.J. L’Hommedieu” is identified, perhaps the final chapter in the tale of Ezra’s double-podded, center-screw auger can finally be written.

Explore!

Read more stories about Connecticut’s Maritime History on our TOPICS page.

Read more stories about products invented and made in Connecticut on our TOPICS page.