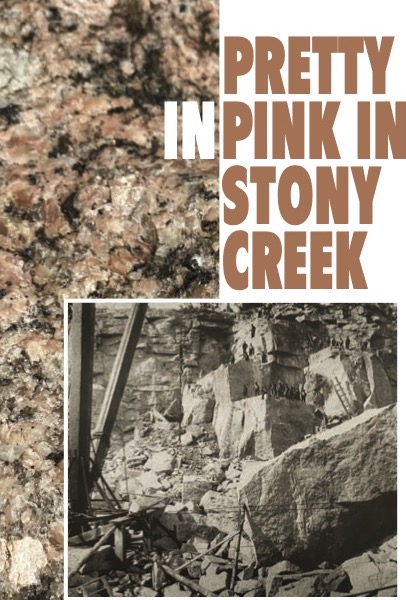

Background: Stony Creek granite. photo: Mary Donohue. Inset: Workers in the southern section of the Dodds Granite Company Quarry, 1925. The large block of stone was blasted out of the ledge; the derrick is to the left. Willoughby Wallace Memorial Library Local History Collection

By Mary Donohue

(c) Connecticut Explored Inc. Spring 2022

Subscribe/Buy the Issue!

Stony Creek granite is one of Connecticut’s most sought-after building materials, one that represents the height of craftsmanship in some of the country’s most iconic structures, including the base of the Statue of Liberty. Connecticut produced other iconic building materials, including Portland brownstone [See “The Quarry that Built Boston and New York City,” Summer 2008.] and Canaan marble. But the country’s best architects and builders were drawn to the unique color of Stony Creek granite.

As geologist Jay Ague describes in Flesh and Stone: Stony Creek and the Age of Granite (Stony Creek Granite Quarry Workers Celebration, 2000), at 600 million years old, “geologic evidence suggests that … Stony Creek granite is one of the oldest rocks exposed anywhere in New England.” It gets its coveted pink color from the reddish mineral potassium feldspar with traces of iron.

Large-scale granite quarrying and stone finishing was impractical until new technology produced steam-powered tools in the 1840s and compressed-air tools in the 1870s. Fifteen pink-granite quarries are documented in Flesh and Stone and located between Branford and Guilford harbors. “Between 1880 and 1895,” The Hartford Courant reported on December 17, 1916, “wealthy men discovered that vast quantities of granite lay in the hills and ledges from half a mile to a mile back of [Long Island Sound]. They bought the land for a trifle and opened quarries. They brought in foreign workers by the carload, cut spur tracks from the quarries to the Shore Line railroad, leased the large hotel, opened a stone yard on its lawn and built a dock in front of it.” Stone was shipped by rail and on their own schooners.

Statue of Liberty, constructed in 1886, 2017. The pedestal, as tall as a 10-story building, was built with Stony Creek granite.

photo: Carol M. Highsmith’s America Project, Carol M. Highsmith Archive, Library of Congress

The first quarry was opened in Branford in 1858 by Benjamin Green, according to Liza Carroll’s “A Brief History of Stony Creek Quarries” on the Town of Branford website. By 1900 as many as 1,800 men were employed there. Many were immigrants with stone-working experience from their home countries. A workforce primarily from the British Isles (Irish, Cornish, and Scottish) grew to include Germans, Swedes, Finns, Spaniards, and Portuguese men.

In 2017 Carl A. Balestracci Jr., the grandson of two Stony Creek quarrymen, published John Beattie and His Quarrymen: Building America Stone by Stone (Guilford Keeping Society) Beattie, a Scottish master stone mason by trade, bought property in 1869 in Guilford, eventually owning more than 325 acres. To support his operations, by the 1880s he had built a small village known locally as “the Patch,” with workers’ housing, a company commissary, and social hall.

The quarrymen were true craftsmen and, as with many jobs of the era, the work involved health hazards and frequent industrial accidents. As described in Flesh and Stone, the quarrying process involved drilling holes into the stone, filling them with blasting powder, and setting the powder off to loosen a large block of stone. The quarrymen then used derricks to lift the stone out of the quarry. It was then moved by rail or a sled pulled by oxen to where it was sized, shaped, and polished to meet the specifications of the contract. Specialized jobs included blacksmith, derrickman, engineer, powderman, stone cutter, and tool boy.

Foremost among the health hazards of the job was silicosis, a condition in which damage to the lungs was caused by inhaling stone dust, similar to “black lung” for coal miners and “white lung” for textile workers. Silicosis ultimately causes the lungs to hemorrhage and is fatal. Other hazards were falls, injuries by a powder blast, or by being crushed under a stone slide.

Dozens of buildings and monuments have been identified as being made of Stony Creek granite, but perhaps the most famous is the base for the Statue of Liberty in New York City. The statue was a gift from France, but the American people had to provide the base on Bedloe Island in New York Harbor. In 1882 John Beattie won the contract to provide the granite for the pedestal. Designed by high-profile New York City architect Richard Morris Hunt, the foundation and base are 154 feet tall. Beattie was invited to the statue’s opening ceremony on October 28, 1886.

Many quarries closed around the time of World War I due to a decline in demand. Today the Stony Creek Quarry Corporation is the sole supplier of pink granite, used in 2019 on the stairs and plaza of the new Statue of Liberty Museum. The former Norcross Brothers Quarry has been listed on the National Register of Historic Places. Hikers can see remnants of the granite industry along the trails of the Stony Creek Quarry Preserve in Branford.

Mary Donohue is assistant publisher of Connecticut Explored and co-producer of Grating the Nutmeg, the podcast of Connecticut history.

EXPLORE!

Stony Creek Museum

84 Thimble Island Road, Stony Creek.

Open seasonally. Stonycreekmuseum.org

Stony Creek Quarry Preserve

Quarry Road, Branford

branfordlandtrust.org/wp-cont3nt/uploads/2014/01/QuarryVanWieKelley.pdf

GO TO NEXT STORY

GO BACK TO SPRING 2022 CONTENTS