(c) Connecticut Explored Inc. SPRING 2004

Subscribe/Buy the Issue!

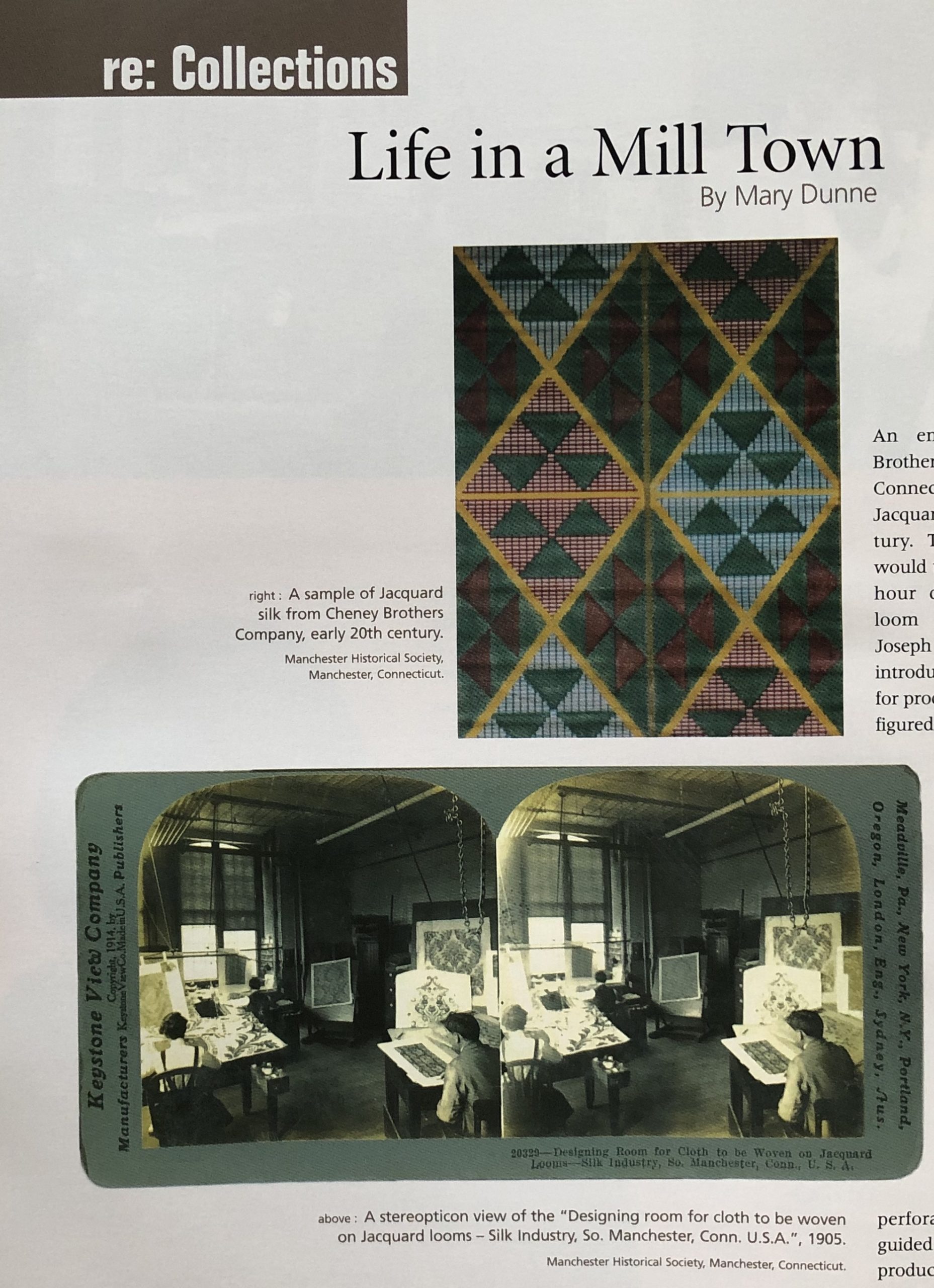

An employee of the Cheney Brothers Company in Manchester, Connecticut, produced this piece of Jacquard silk in the early 20th century. The employee, a weaver, would typically have worked a 12-hour day operating a Jacquard loom (named for Frenchman Joseph Marie Jacquard who first introduced an automated process for producing elaborate patterns for figured or brocaded goods).

Cheney Brothers often created designs such as this by modifying historic fabrics from the 17th through 19th centuries. They also purchased designs from import houses or directly from Europe. Design in hand, the first step in the Jacquard weaving process was to create the project pattern draft by transferring the design to paper, which was ruled in squares representing the intersections of the warp and filling threads. Next, perforated Jacquard cards that guided the loom’s motions were produced. A chain of hundreds or even thousands of such cards would be used to “instruct” the loom to create the desired pattern. Cheney Brothers began making upholstery fabric around 1885 and by the early 20th century, after years of refining the process and building a skilled work force, had attained a reputation for producing the finest Jacquard woven silks in the United States.

What was life like for the average worker at the Cheney Brothers silk mills? Prior to 1861, the company’s main product was silk thread for sewing. After the Civil War, operations expanded to include the weaving of broad goods for garments and Jacquard weaving for upholstery, a product for which they became renowned worldwide. At the height of its success during the early 1920s, Cheney Brothers had over 4,500 workers on its payroll. The next 14 largest businesses in Manchester employed less than 900 workers, combined.

Despite Cheney Brothers’ dominance, the number and diversity of other industries in town prevented Manchester from becoming a “Company Town” in the strictest sense. Nonetheless, the Cheney family’s influence was profound. First of all, they lived and worked among their employees. Most other mills in town had absentee owners who employed mill agents and supervisors. The Cheney family believed they had a responsibility to their community. They built public schools, libraries, and utilities, donated land for churches, and, in 1867, built Cheney Hall, a center for recreation and entertainment that was open to employees and townspeople alike. Near their factories, the Cheneys built rental housing for employees and made loans available for their purchase.

The Cheney’s efforts attracted the attention of Harper’s Magazine , which reported in 1872:

Manchester is one of the finest specimens of a manufacturing village. It occupies an undulating site of great natural attractiveness. Hundreds of working men and their families, intelligent, thrifty and self-respecting, live on the best of terms with their employers. There is scarcely a hint of factory life about the scene.”

Cheney Brothers believed that creating favorable conditions would foster company loyalty and a low employee turnover rate. Although wages were not notably generous, employees received accident and health insurance, death benefits, and pensions. One worker who spent almost 60 years in the velvet mill recalled in the book The Storytellers , “I don’t know if they were just handing out their money indiscriminately, but regarding anything that seemed to benefit the town and thereby their own workers, they seemed to be very generous.”

The Cheney’s paternalistic attitude toward employees resulted in a fairly stable workforce. Some families had multiple generations employed at the mills. The happy by-product for the company was a labor force that did not see a need to organize. A 1937 history of the company, written by the Cheneys, states, “.throughout the whole history of the firm labor troubles have been at a minimum.” In fact, organized worker unrest was nonexistent until 1902 when the firm moved to pay the same rate for a velvet weaver to operate two looms at one time instead of one. The workers went on strike from March to October of that year. During this period there were several attempts to organize labor, but by the end of the strike no union existed.

Although the Cheney Brothers silk mills have long been closed, the legacy of both the Cheney family and their thousands of employees remains in Manchester. Cheney Hall still presents community concerts and theatrical productions, and the life of Cheney’s workers can be relived through exhibits at the Manchester Historical Society.

The Manchester Historical Society is open year-round on Friday and Saturday from 10 A.M. – 4 P.M. and Sunday from 1- 4 P.M. For information call 860-647-9983 or visit the society’s Web site at www.manchesterhistory.org.

Mary Dunne was the Executive Director of the Manchester Historical Society.

Explore!

“Cheney Brothers: Innovations in Silk,” Spring 2005

Destination: Cheney Hall, Fall 2002

“The Cheney Company Housing Auction of 1937,” Spring 2013

Silk Production: “Connecticut’s Mulberry Craze,” Spring 2018

Read more about Labor History in Connecticut on our Topics page

Read more about Connecticut-made products on our Made in Connecticut Topics page.